The v1 of the Manufacturing Inventory and Sales Manager was retired in July 2015. Latest version is Manufacturing Inventory and Sales Manager Excel Template v2 (released in July 2015). This post contains information related to v1. If you are still using v1, please see below for help.

ABOUT THE EXCEL TEMPLATE

This Excel template helps in managing inventory at a manufacturing/assembly business. If you buy raw materials and convert them to products by assembling or manufacturing, then you can use this template to manage inventory of products and raw materials. You can save time by the automatic calculation of current inventory levels of products (finished goods) and also products (in the form of raw materials). All the order details will be managed in one place and you can see purchase and sales trends instantly in this Excel template.

REQUIREMENTS:

Windows: Microsoft Excel 2010, Microsoft Excel 2013

PRODUCT TOUR VIDEO:

PRODUCT DEMO VIDEO:

SETTINGS

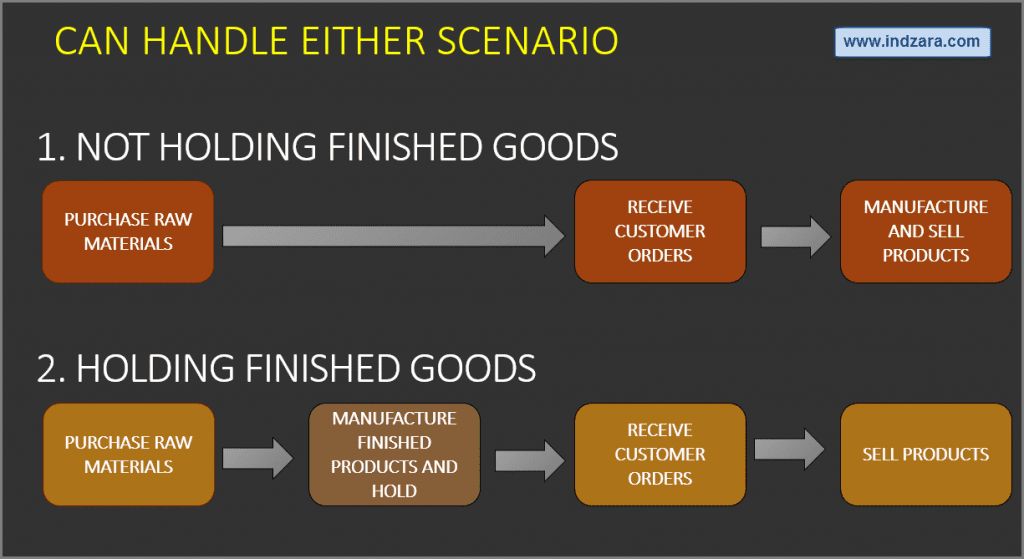

The template can handle two different scenarios.

- Scenario 1: Buy raw materials from suppliers, receive customer orders and manufacture products and sell them.

- Scenario 2: Buy raw materials from suppliers, manufacture products and hold them, and sell them to customers when you receive orders.

In the first scenario, you are not holding finished goods. In the second one, you are. Before you begin using the template, choose the setting that is appropriate for your business.

1. PRODUCTS

Enter products in the PRODUCTS sheet. Each line should be a separate product.

- Description of the product for your reference.

- Product Category: This allows you to categorize products. If you have numerous products, categorizing similar products together can help in understanding product performance.

- Re-order point. Quantity that you set for each product, where when the current inventory level hits that amount, you will place a new purchase order to replenish inventory. (For more, read Wikipedia article https://en.wikipedia.org/wiki/Reorder_point)

- Starting Inventory: Quantity of Product that you have as finished goods when you begin using this template. Enter only once.

2. RAW MATERIALS

Enter list of raw materials in the RAW MATERIALS sheet. Each line should be a separate raw material.

- Name of the Raw material. Unique Raw Material names required.

- Description of the Raw Material for your reference

- Raw Material Category: This allows you to categorize Raw materials. If you have numerous raw materials, categorizing similar ones together can help in understanding performance.

- Starting Inventory: Quantity of Raw material that you have when you begin using this template. Enter only once.

3. MANUFACTURING DETAILS

Enter details on how raw materials are converted to products. In the image below, please see rows 1 to 3. You can see that 1 Banana, 5 Strawberries and 10 Blueberries are needed to make 1 unit of Banana Berry Shake (L). See rows 4 and 5. 2 Apples and 2 Bananas are needed to make Apple Banana Shake (L). The Excel template can now understand how inventory needs to be calculated for raw materials and products.

4. ORDER DETAILS

It’s time to enter the order details. If you hold finished goods inventory, then there are three types of Orders. Purchase, Sale and Mfg.

- Purchase Order: When you place an order to acquire raw materials from suppliers.

- Sale Order: When your customer places an order to buy products from you.

- Mfg Order: When you manufacture goods and store as finished goods, choose Mfg as Order Type. If you don’t hold finished goods inventory, please do not use Mfg order type.

- ORDER NUMBER: Order number is not used in the template to calculate anything. This has been provided for you to track your orders easily. You can filter the Orders table by choosing specific order number to see all the items in that order. If your systems generate any order numbers, you can enter them here. If you don’t have any such systems, you can create your own. The only recommendation is that you should have a unique order number for each order.

- ORDER DATE:

- For Purchase orders, this is the date when the order is placed by you to your supplier.

- For Sale orders, this is the date when the order is placed by your customer to you.

- For Mfg orders, this is the date when you placed an internal order to manufacture.

- EXPECTED DATE:

- For Purchase and Mfg orders, this is the date when the inventory becomes available for you to sell.

- For Sale orders, this is the date when the inventory will leave you to the customer.

- PARTNER:

- For Purchase orders, your supplier is the Partner.

- For Sale orders your customer is the Partner.

- For Mfg orders, you can choose ‘Self’ as the Partner name, since you are manufacturing and holding the finished goods yourself.

- PRODUCT NAME:

- For Purchase orders, enter raw material name.

- For Sale and Mfg orders enter product name.

- QUANTITY: Number of units of products. The unit can be any numeric value. Even if your unit is not whole numbers, you can still use the Quantity field.

- UNIT PRICE:

- In Purchase orders, this is the cost of buying one unit of the product. In Sale orders, this is the revenue from selling one unit of the product. For Mfg orders, it is the cost of manufacturing one unit of product.

- AMOUNT (Calculated field): (Unit Price X Quantity) = represents the amount of money. In Purchase orders this would be money leaving you and in Sale orders, this would be money that customers pay you. In Mfg orders, this is the amount it spent to manufacture.

REFRESH DATA

After entering any data in the template, please refresh. You can do so by pressing ‘Refresh All’ from DATA Ribbon.

INVENTORY LEVELS

You can instantly view overall current inventory levels (Products available, Quantity and also number products to be re-ordered).

CHECK INVENTORY AVAILABILITY

You can see availability of any product by selecting it from the drop down menu.

5. PRODUCT REPORT

View the product report (fully automated) which provides all the inventory information at the product level. The report by default shows the first 1000 products, but you can extend the table by filling down.

- STARTING INVENTORY: This is the information you provided in Products sheet at the beginning.

- SALES: Units of the product sold until (and including) today

- CURRENT INVENTORY (FG) Units of the product currently in inventory as finished goods. = Starting inventory + Manufactured quantity – Sales quantity

- CURRENT INVENTORY (RM) Units of the product that can be manufactured based on currently available raw materials

- TOTAL INVENTORY: Units of product that are either available as finished goods or as raw materials. CURRENT INVENTORY (FG) + CURRENT INVENTORY (RM)

- TO ORDER?: If total inventory is less than or equal to Re-Order Point of product, then ORDER, else NO. You can choose only products to order by selecting ORDER in the filter.

- SALES RANK: This is the sales rank of the product.

- Please note that if you have applied filters in SALES_REPORT sheet (which we will see in a few minutes), then SALES RANK will update accordingly.

6. RAW MATERIALS REPORT

View the report (fully automated) which provides the inventory information for each raw material. The report by default shows the first 1000 products, but you can extend the table by filling down.

- STARTING INVENTORY + PURCHASES: Units of raw materials in Starting Inventory + Units purchased until (and including) today

- USED (TILL NOW): Units of raw materials used in manufacturing products until (and including) today

- AVAILABLE NOW: Units of raw material available today for use

7. SALES REPORT

Sales report (fully automated) allows drilling down into the purchase and sales trends overall and also for each product or category.

Purchase and Sales (Qty and Amounts) in the last 36 months.

Amount contribution % by product category

Identify the top 10 products by Sales Amount