Raw Material Inventory Management 2025 in Excel

This free inventory tracker template is designed for small businesses which manufacture or assemble products from raw materials.

You can use this manufacturing inventory management excel template to automatically calculate the current raw material stock as well as determining how many units of each product you can make using the raw materials available.

We can input simple Bill of Materials (BOM) where we define how we can manufacture a products from its raw materials. We let the template take care of all the calculations.

Free Download

Video Tour

How to track raw material inventory in Excel

There are five sheets in the raw material inventory management excel template: 1) Home 2) Products 3) Raw Materials 4) BOM and 5) Orders

Overview of steps

- Enter Products in Products sheet

- Enter Raw Materials in Raw Materials sheet

- Enter Bill of Materials in BOM shet

- Enter orders in Orders sheet after checking availability

- View Current raw material stock in Raw Materials sheet

Steps in Detail

I will use an example of a Juice/Smoothie company which creates juices from fruits & vegetables. However, this template can be used in any industry.

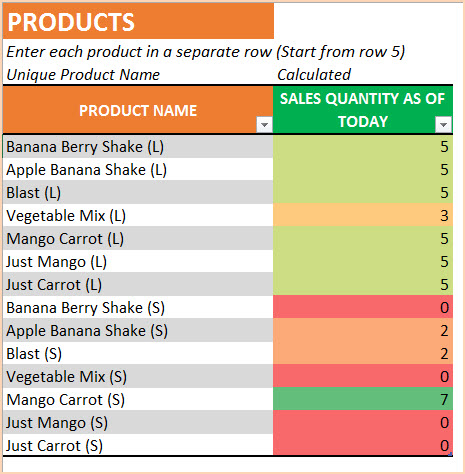

Enter list of parts or products in the Products sheet as shown below

The Sales Quantity column is calculated based on sales orders that we will be entering soon.

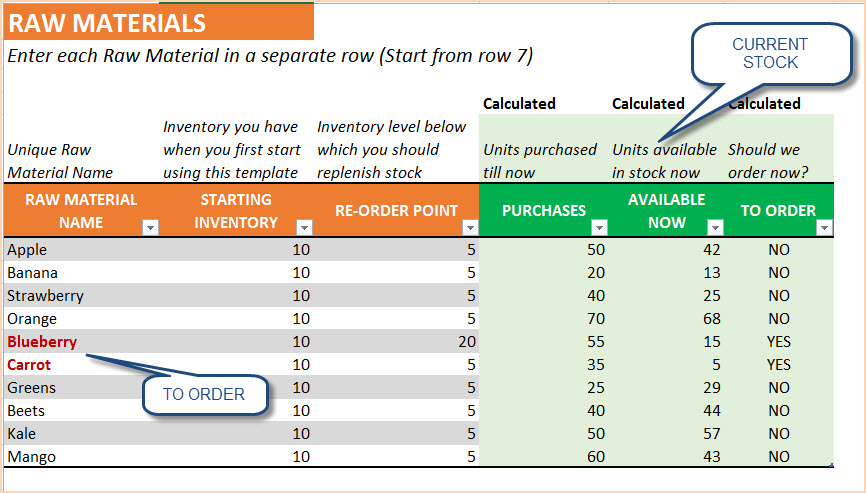

Enter list of raw materials you use in your business in the Raw Materials sheet.

- Starting Inventory: In this sample data, we have 10 Apples and 10 Bananas in stock when we begin using the template.

- Re-Order Point: We have re-order points (Wikipedia Article on Re-Order Point) set for each raw material.

- Available Now: Displays the current stock level of each raw material.

- To Order: When current stock for a raw material goes below its re-order level, this field displays YES. Also, the template highlights the raw material name in red font.

Use this raw material stock register format in excel to handle all your raw materials availability.

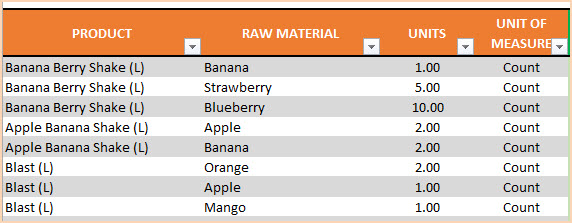

Enter Bill of Materials (BOM) in BOM sheet

In the sample above, 1 unit of Banana Berry Shake is created from 1 Banana, 5 Strawberries and 10 Blueberries. 1 unit of Apple Banana Shake is created from 2 Apples and 2 Bananas. Unit of Measure column is just for your reference.

Once you have entered BOM for all your products, the initial set up is done.

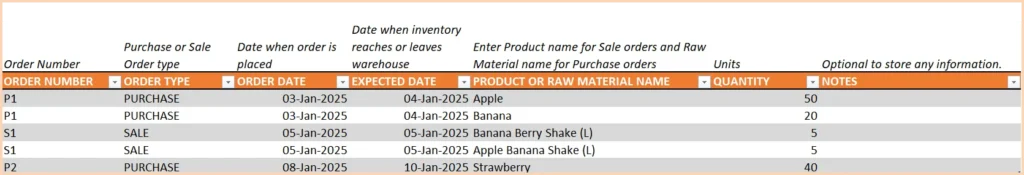

Entering purchase and sale orders in Orders sheet.

As a manufacturing business, you may buy raw materials from your suppliers and sell the finished products to your customers. So, there are two key transactions – Purchase and Sale.

We can enter Purchase and Sale Orders in a single table in Orders sheet.

- Order Type: Order P1 is to purchase 50 Apples and 20 Bananas – So, we use Order Type of PURCHASE. Order S1 is an order to sell 5 Banana Berry Shakes. We use SALE order type.

- Order Date: Date when the order is placed.

- Expected Date: Date when the inventory is impacted. For example, order P1 was placed on 3rd Jan, but raw materials will reach us only on 4th Jan. So, Order date is 3rd Jan and Expected Date is 4th Jan.

- Product or Raw Material Name: The template allows drop down selection for product / raw material name. If the order type is Purchase, it will allow Raw Materials and if order type is Sale, it will allow Products.

- Quantity: Enter quantity or units of items on the order

If an order has 5 line items, then enter as 5 rows.

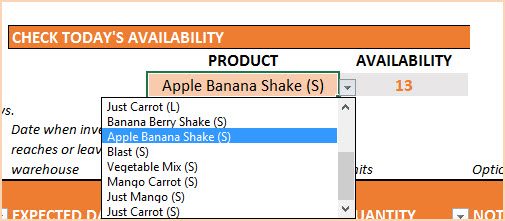

Check Availability

Before entering a new Sale order, if you would like to check the current capacity for a product, you can easily do that.

When you select a product, the template runs the calculations to figure out how many units of the product can be manufactured using the raw materials in stock right now. In the image above, we see that we can make 13 Apple Banana Shakes.

Limit

This free excel template for manufacturing company cannot handle complex scenarios where sub-assemblies of raw materials are raw materials to the final product.

Related free Inventory Management Templates

- Retail Inventory Tracker (Free)

- Rental Inventory Tracker (Free)

Recommended Template for Manufacturing Businesses

Manufacturing Inventory & Sales Manager (Inventory, Orders, Invoice, Sales Reporting, Customer Data Management)

178 Comments

Hi

this template does not factor in damages during production or defects to give me the total number of raw material left. May you kindly assist?

Thanks for using our template.

This template does not account for damages during production or defects. We have noted your feedback and try to incorporate this feature in the future releases.

Best wishes

How can I use this to look ahead, based on my expected delivery dates?

Hello

The expected date provides the date when the inventory gets impacted. Please share more details, maybe with an example.

Best wishes

Wonderful template. Thanks a lot.

As I am trying to edit this template, I would like to check with you ig you already have remade temple for my use case.

I have a manufacturing unit which makes concrete blocks of different sizes.

Now I will be having raw materials and finished product stock.

So I need a way to track both the raw materials and the manufactured stock.

Thanks in Advance!

Thanks for using our template.

Please review our Manufacturing – Inventory and Sales Manager – Excel Template at https://indzara.com/product/manufacturing-inventory-sales-manager-excel-template/

Best wishes

Just want to tell you how awesome this spread sheet is. We are a small craft based provider of custom jewelry and needed a BOM and Inventory system. Your spread sheet is the perfect solution as we can now account for the components that go into each item and reduce the inventory levels with each sale. This has improved our costing abilities as well.

Thanks for using our template and sharing a positive experience.

We always endeavor to exceed expectations.

Best wishes

Excellent web site. A lot of helpful info here. I’m sending it to some pals ans additionally

sharing in delicious. And certainly, thanks in your effort!

Thanks for sharing your wonderful experience.

Is there any way to adjust the inventory levels aside from Purchases and Sales. If we need to adjust a quantity after counting the stock does the template offer an adjustment entry?

Thanks for using the template. Currently, that is the only way to adjust inventory levels. Please try entering a dummy sale order to reduce inventory.

Best wishes.

Hi!

Do you have any solutions that overcome the limit of sub-assembling raw materials that are raw materials to the final product?

Thanks for your message.

The template is not designed to handle the sub assembling to the other raw materials. We might have this feature in the next release.

Best wishes

I entered data in the available now field in my Manufacturing Inventory Tracker and it stopped calculating that row. Is there any way to correct this without downloading the spread sheet and starting over?

Thanks for using our template.

Please ensure that none of the formulas are missing. If the issue persists, we will advise you to download the template again.

Best wishes

Hi how can I download this template

Thanks for your message.

Please download the file from the Free Download section of https://indzara.com/2016/08/free-manufacturing-inventory-tracker/

Best wishes

Once downloaded can I use the Manufacturing – Inventory and Sales Manager – Excel spreadsheet in multiple computers?

Thanks for your message.

Our templates have a single-user license.

Best wishes